Questions about inventory management? Our professional team is here to help.

The Key to Supply Chain Success: Proper Inventory Management

Inventory is one of the most valuable assets for any growing business. Effective inventory management ensures a business can meet customer demands, maintain optimal inventory levels, and reduce excess stock. Without a proper inventory management system, businesses face stock discrepancies, fulfillment delays, and financial inefficiencies.

Business owners must adopt inventory management software to track raw materials, finished goods, and overall inventory accounts. Whether handling a small business or a company managing multiple warehouses, investing in the right tools is critical to success.

The Foundations of Effective Inventory Management

Proper inventory management involves tracking inventory, maintaining accuracy, and optimizing stock control. Key areas include:

- Inventory Control – Ensuring accurate tracking of raw materials and finished goods.

- Online Inventory Management – Using cloud-based tools for real-time data access.

- Order Fulfillment – Streamlining processes to fulfill orders efficiently.

- Replenishment Planning – Maintaining inventory levels using economic order quantity (EOQ) methods.

- Inventory Valuation – Determining the financial value of physical inventory.

- Shipping Labels & Serial Numbers – Ensuring accurate identification and tracking of inventory items.

Without a structured approach, inventory mismanagement can lead to supply chain bottlenecks, lost sales, and excess carrying costs. By leveraging the right inventory software, businesses can improve inventory accuracy and reduce inefficiencies.

The Role of an Inventory Management System

Tracking Inventory with Data Transparency

Managing inventory requires real-time insights into stock levels, movement, and replenishment schedules. Inventory management software provides:

- Automated tracking of raw materials and finished products.

- Custom reporting tools for inventory valuation and forecasting.

- Barcode scanning and serial numbers for efficient inventory account updates.

- Inventory alerts to prevent stock shortages and overstocking.

For business owners handling multiple warehouses, inventory software ensures consistency across locations and prevents stock discrepancies.

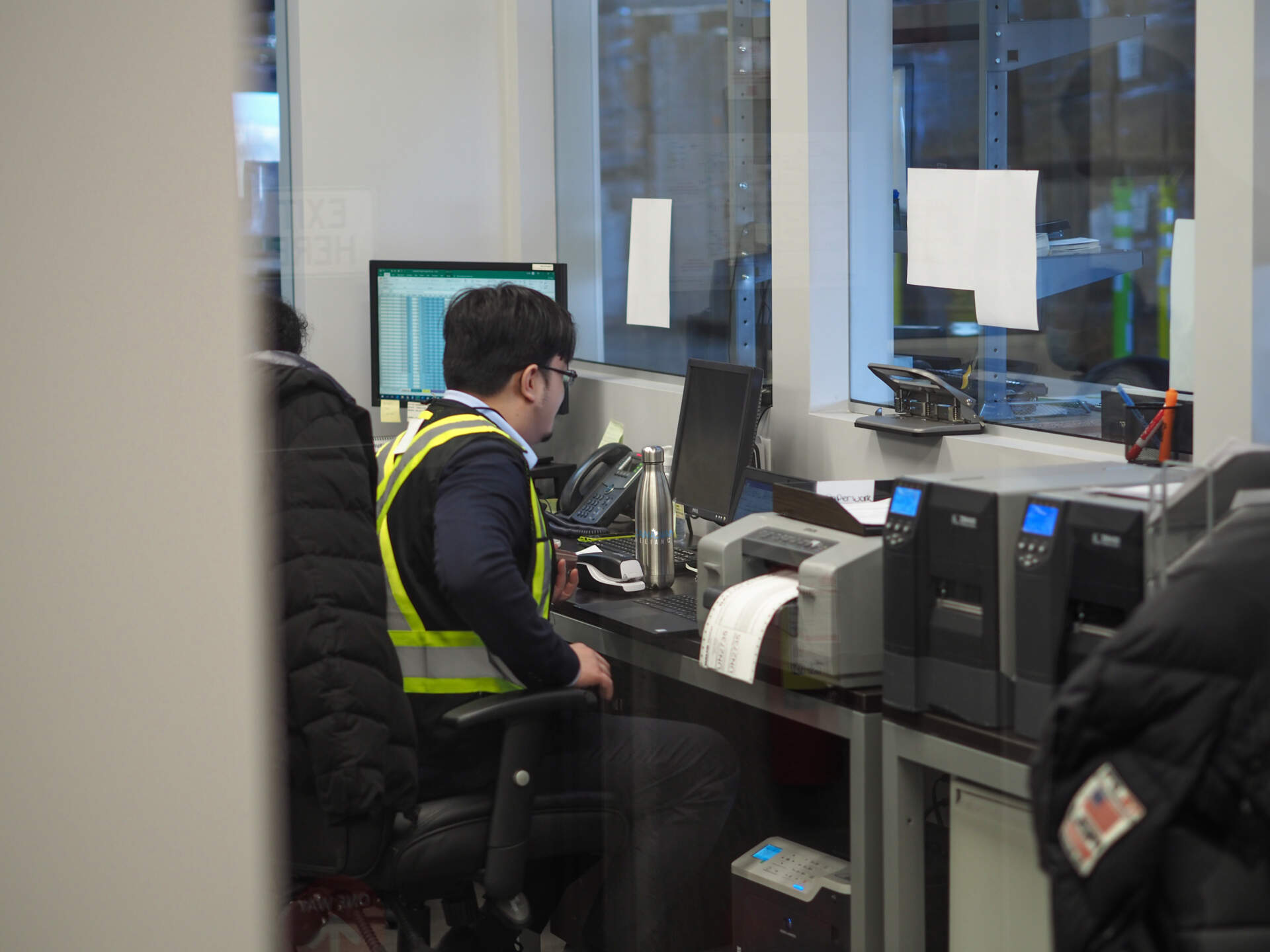

Canadian Alliance uses Extensiv’s warehouse management system (WMS) which integrates seamlessly and transparently with customers’ inventory management systems.

System Integration for Efficiency

Modern inventory software integrates seamlessly with:

- Enterprise Resource Planning (ERP) Systems: Connecting inventory accounts with financial records.

- Warehouse Management Systems (WMS): Optimizing large warehouses for improved order fulfillment.

- E-commerce Platforms: Enabling inventory synchronization with an online store.

- Point of Sale (POS) Systems: Tracking sales data to adjust inventory levels.

- Transportation Management Systems (TMS): Enhancing inbound and outbound logistics for timely deliveries.

These integrations provide a centralized approach to managing inventory, improving accuracy, and reducing operational costs.

The Importance of a Reliable 3PL Partner

A well-structured inventory management system is critical, but having a reliable third-party logistics (3PL) partner can take efficiency to the next level. A 3PL provider offers warehousing, fulfillment, and distribution services that support businesses of all sizes. The right 3PL partner can help:

- Enhance Order Fulfillment: With strategic warehouse locations, businesses can fulfill orders faster and reduce shipping costs.

- Reduce Overhead Costs: Outsourcing logistics eliminates the need for maintaining large warehouses and hiring additional staff.

- Improve Scalability: Growing businesses benefit from flexible storage and distribution solutions tailored to their needs.

- Optimize Transportation Management: 3PL providers streamline inbound and outbound logistics, ensuring faster, cost-effective deliveries.

- Increase Inventory Visibility: Many 3PLs offer integration with inventory management software, providing real-time tracking of stock levels and shipments.

Partnering with a trusted 3PL provider ensures that businesses can focus on core operations while maintaining high service levels and operational efficiency.

Best Practices for Inventory Optimization

1. Automate Replenishment Using Inventory Management Software

Automating replenishment reduces human error and improves inventory turnover. Key benefits include:

- Maintaining optimal inventory levels with economic order quantity (EOQ) strategies.

- Preventing stockouts and overstocking.

- Reducing holding costs and freeing up cash flow.

- Enhancing supply chain efficiency with just-in-time inventory practices.

2. Monitor Inventory Turnover Rates

Tracking inventory turnover helps businesses maintain proper stock levels. A low turnover rate may indicate excessive inventory, while a high rate may suggest frequent stockouts. To improve turnover:

- Analyze sales trends and adjust inventory levels accordingly.

- Implement demand forecasting to prevent surplus stock.

- Reduce excess inventory through promotions and markdowns.

3. Optimize Inventory Across Multiple Warehouses

Managing inventory in large warehouses requires careful planning. Best practices include:

- Using inventory management software for stock visibility across locations.

- Balancing stock allocation to prevent shortages and overstocking.

- Implementing automated tracking to monitor physical inventory movement.

4. Conduct Regular Inventory Audits

Even with advanced tracking inventory solutions, physical inventory audits ensure accuracy. Regular audits help:

- Identify discrepancies in inventory accounts.

- Reduce shrinkage due to theft or misplacement.

- Improve warehouse efficiency with optimized storage methods.

5. Leverage Predictive Analytics for Demand Planning

Predictive analytics provides insights into customer demand, helping businesses:

- Adjust stock levels proactively.

- Optimize raw materials procurement for finished goods.

- Enhance just-in-time inventory strategies.

6. Improve Supplier Collaboration

A well-managed supply chain starts with strong supplier relationships. Strategies for improving collaboration include:

- Sharing inventory forecasts to streamline order replenishment.

- Using automated ordering systems to reduce delays.

- Negotiating flexible agreements to adjust inventory levels as demand changes.

The Importance of Quality Control in Inventory Management

Quality control is a critical factor in managing inventory effectively. Businesses should:

- Inspect incoming raw materials to ensure high standards.

- Track finished goods for defects before they reach customers.

- Maintain strict guidelines for inventory handling in large warehouses.

- Use shipping labels and serial numbers to prevent misidentification.

By implementing robust quality control measures, businesses can prevent returns, minimize losses, and improve customer satisfaction.

Future Trends in Inventory Management

As technology evolves, businesses must embrace modern inventory management solutions. Key trends include:

- AI-Driven Inventory Software: Enhancing demand forecasting and stock optimization.

- IoT Sensors for Tracking Inventory: Providing real-time stock movement data.

- Blockchain for Secure Inventory Records: Ensuring transparency in inventory accounts.

- Robotic Automation in Warehouses: Increasing efficiency in large warehouses.

- Sustainable Inventory Management: Reducing waste and improving eco-friendly logistics.

These advancements will help businesses manage inventory with greater efficiency and precision.

Final Thoughts: Why Investing in the Right Inventory Management System Matters

Inventory is at the core of any successful business. Whether managing a small business or a growing business with multiple warehouses, investing in the right inventory management system ensures:

- Lower inventory carrying costs.

- Accurate tracking of raw materials and finished products.

- Seamless fulfillment of online store orders.

- Improved inventory valuation for financial reporting.

- Greater visibility into stock movement with shipping labels and serial numbers.

At Canadian Alliance Terminals, we provide expert solutions for inventory management. Contact us today to learn how our inventory management software can help your business optimize stock control and fulfillment operations.