Questions about supply chain management? Our professional team is here to help.

Why Does Supply Chain Management Matter for Business Growth?

Importers, exporters, and manufacturers rely on complex logistics networks to move goods efficiently, meet market demand, and remain competitive. At the centre of these activities is supply chain management—a critical, yet often underestimated, business function.

Effective supply chain management is more than operational support. It shapes your capacity to grow, adapt, and succeed. But are your supply chain operations truly supporting your goals, or are they quietly draining time, capital, and opportunities?

This article explores the practical role supply chain management plays in business success. It also offers actionable strategies for improving efficiency, minimising risks, and building long-term resilience in a rapidly evolving global market.

What Is Supply Chain Management—and Why Should You Care?

Supply chain management (SCM) refers to the oversight and coordination of all activities involved in sourcing, producing, storing, and delivering goods. For importers, exporters, and manufacturers, SCM determines your ability to meet demand, maintain inventory, and navigate uncertainty.

Strong SCM aligns logistics with business objectives. Weak SCM leads to missed shipments, inflated costs, and lost market share.

Key Supply Chain Management Components:

- Procurement and supplier relationships

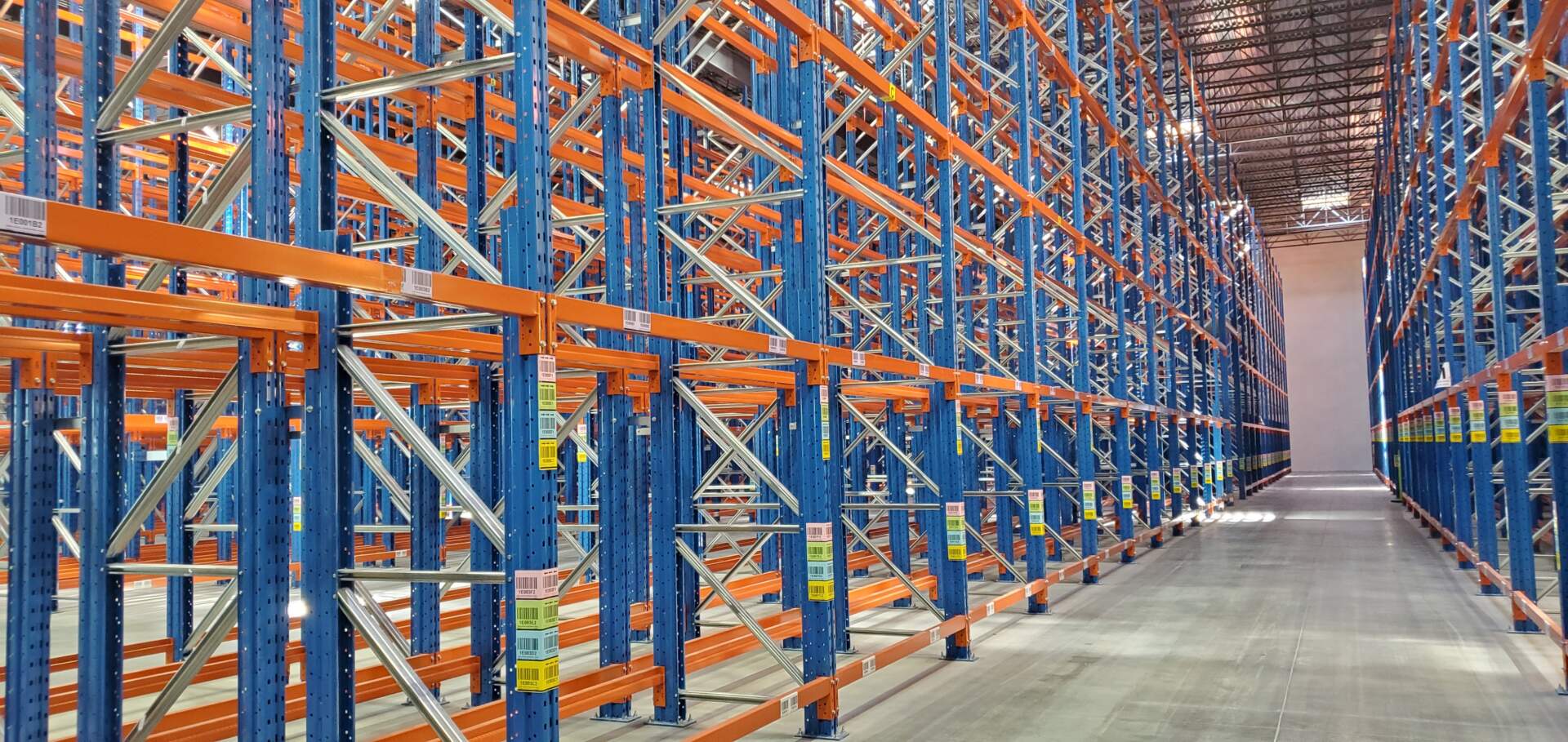

- Inventory management and storage

- Transportation and distribution

- Information systems and data flow

- Risk management and contingency planning

- Sustainability and compliance

When these areas are integrated into your broader operations management framework, the result is a more agile, responsive business.

How Can Supply Chain Strategies Reduce Costs and Improve Efficiency?

Cost control and efficiency are constant concerns for companies in trade and manufacturing. Supply chain operations offer multiple touchpoints where value can be unlocked or lost.

Practical Strategies to Improve Performance:

- Evaluate your suppliers regularly. Are they still cost-effective, reliable, and aligned with your business process?

- Optimise order quantities. Use demand forecasting tools to prevent overstocking and stockouts.

- Use regional warehousing. Consider working with third-party partners like Canadian Alliance Terminals to reduce transit times and inventory holding costs.

- Streamline transport routes. Consolidate shipments or shift modes (e.g., from air to rail) when feasible.

- Automate repetitive tasks. Order processing, invoicing, and shipment tracking are ideal candidates for automation.

These strategies not only cut costs but also improve service levels and internal productivity—giving you a competitive advantage in both domestic and international markets.

How Is Technology Transforming Modern Supply Chains?

From artificial intelligence to the Internet of Things (IoT), emerging technologies are redefining the way supply chains operate. But adoption is not just about staying current—it’s about staying ahead.

Key Technologies Impacting Supply Chain Management:

- IoT sensors track shipments, monitor conditions (e.g., temperature, humidity), and provide real-time visibility.

- Blockchain ensures secure, tamper-proof records, particularly useful in verifying product origin and preventing fraud.

- AI and machine learning support demand forecasting, route optimisation, and predictive maintenance.

When integrated into your information systems, these tools can drive better operations management and support long-term business process improvements.

In British Columbia, logistics hubs such as the Port of Vancouver increasingly require digital integration for inbound and outbound coordination. Working with partners that embrace this technology is essential for efficient cross-border movement and inventory management.

What Role Does Risk Management Play in Supply Chain Resilience?

Supply chain disruptions—from global pandemics to natural disasters—have become more frequent and more costly. Businesses without strong risk management protocols are left vulnerable to delays, rising expenses, and customer dissatisfaction.

Key Elements of Supply Chain Risk Management:

- Diversify suppliers and transport options to avoid single points of failure.

- Use predictive analytics to identify emerging risks and plan responses.

- Maintain buffer inventory for high-risk or high-demand items.

- Develop contingency contracts with alternative logistics providers.

For instance, Canadian companies dependent on U.S. border transit must prepare for delays caused by policy changes or inspection backlogs. A Vancouver-based logistics partner with cross-border expertise, such as CAT, can support more resilient supply chain operations through contingency planning and local responsiveness.

How Can Businesses Develop Skills and Capabilities in Supply Chain Management?

Successful SCM requires more than good systems—it requires skilled people. As supply chains grow more complex, the need for well-rounded professionals who understand logistics, data analytics, sustainability, and international trade continues to grow.

Ways to Develop Internal Supply Chain Capabilities:

- Invest in professional development for your logistics and operations teams.

- Encourage cross-functional collaboration between procurement, sales, and finance.

- Adopt user-friendly information systems that empower staff with real-time data and reporting.

- Engage external experts or 3PL providers to fill capability gaps without overextending internal teams.

Canadian businesses that develop supply chain skills in-house—while leveraging external logistics partners—gain greater agility, better forecasting, and improved responsiveness in the face of change.

How Can You Build a More Sustainable Supply Chain?

Sustainability in supply chain management is not just a corporate social responsibility checkbox—it is increasingly a business necessity. Stakeholders, from customers to regulators, expect companies to reduce their environmental footprint and operate transparently.

Sustainable Supply Chain Practices to Adopt:

- Reduce transport emissions through route optimisation and modal shifts.

- Choose environmentally certified suppliers and materials.

- Implement packaging reduction initiatives that minimise waste.

- Use local warehousing to reduce long-distance hauling and fuel usage.

In British Columbia, companies must also comply with regional environmental regulations such as the CleanBC initiative, which aims to reduce carbon emissions and improve energy efficiency across industries.

CAT, for example, works with clients to optimize warehousing strategies that reduce waste, lower emissions, and support more responsible supply chain operations.

How Should Importers, Exporters, and Manufacturers Approach Supply Chain Management in Canada?

For companies operating in Canada or moving goods across borders, local knowledge and regulatory compliance are just as important as global strategy. Navigating customs, provincial safety regulations, and infrastructure constraints requires local expertise.

Key Considerations for Canadian Supply Chain Management :

- Customs documentation and trade agreements (e.g., CUSMA, CPTPP)

- WorkSafeBC compliance in warehouse environments

- Multimodal access via ports, rail, and road networks

- Geographic distribution to serve East, West, and Central Canada efficiently

Partnering with a logistics provider familiar with Canadian regulations and infrastructure—such as CAT—ensures smoother supply chain operations and fewer administrative delays.

What Questions Should You Ask When Evaluating Supply Chain Management Strategies?

Assessing your current supply chain can uncover opportunities for improvement. Start with these self-assessment questions:

- Are your current operations scalable and sustainable?

- Do you have visibility into your full supply chain—from supplier to customer?

- Are disruptions managed proactively, or only after damage is done?

- Is your inventory management system delivering the data you need?

- Are your logistics partners contributing to your business process goals?

If your answers raise concerns, it may be time to invest in new strategies, tools, or partnerships to strengthen your supply chain management framework.

Conclusion: Invest in Better Supply Chain Operations Today

The future of business belongs to those who can manage change, reduce waste, and respond quickly to demand. Supply chain management is not an administrative function—it is a driver of growth, innovation, and resilience.

Whether you’re expanding globally, scaling locally, or stabilising post-growth, the right supply chain solutions will underpin your success.

Canadian Alliance Terminals partners with importers, exporters, and manufacturers to deliver smart, sustainable supply chain operations—customised to your goals and built to grow with you.

Contact us today to find out how we can support your business through efficient, scalable, and forward-thinking logistics.